Fax:86-0769-82389116

Email:Sales@harber-mim.com

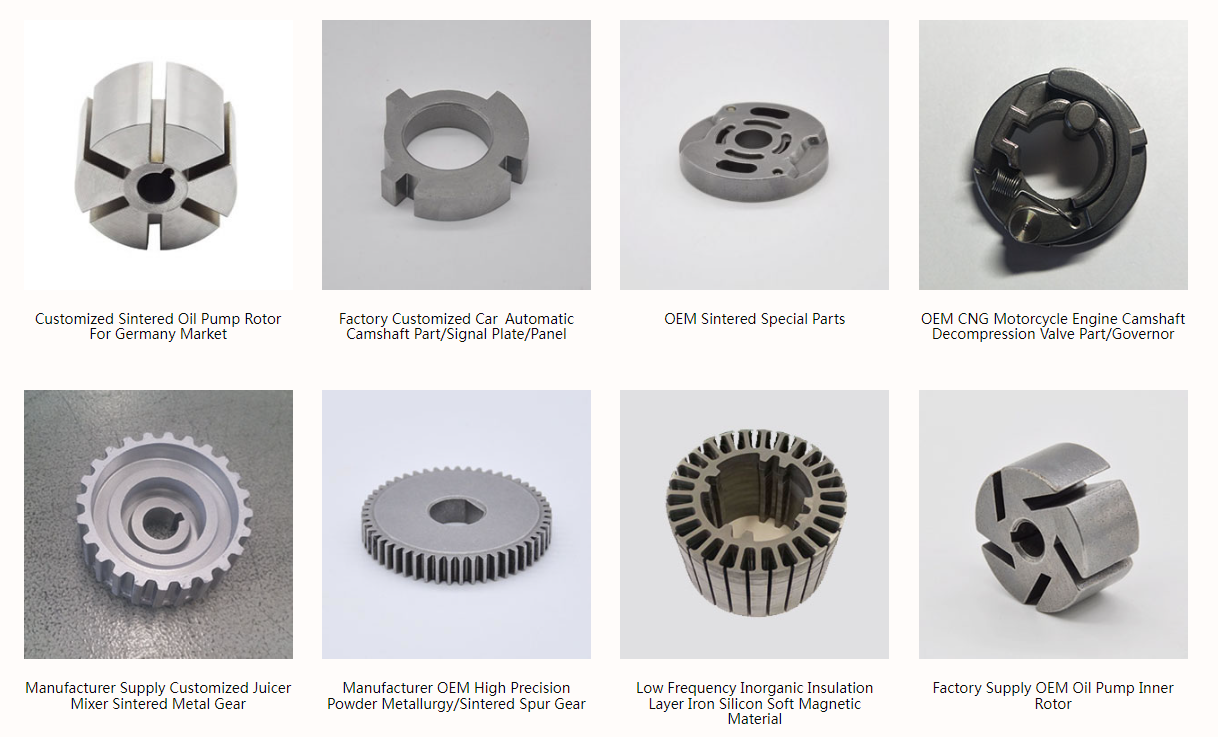

Metal injection molding (MIM) is a unique molding process for metal parts. It is mainly suitable for producing metal parts with high melting points, such as iron-based alloy steel, stainless steel, nickel-based alloy, tungsten alloy, titanium alloy, etc. Currently, the most common industrial application of MIM is the mass production of stainless steel parts, which we call MIM stainless steel or SS part molding. For example: earbuds SS parts, small gears, watch cases, etc.

MIM material

| Material | Composition |

| Low alloy steel | Fe-2Ni, Fe-8Ni |

| Stainless steel | 316L, 17-4-PH |

| Tool steel | 42CrMo4, M2, Skd-11, C45 |

| Carbide | WC-Co(6%) |

| Ceramics | Al203, ZrO2, SiO2 |

| Tungsten alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

1. Reduce the processing difficulty: forming at a lower temperature greatly reduces the processing difficulty.

2. Be able to make complex shape and structural parts like plastic injection molding.

3. High dimensional accuracy: adopt multi-channel processes such as mold forming, sintering and shaping, and the products have good dimensional accuracy and interchangeability.

4. Mold forming is adopted, with high production efficiency, suitable for mass production and low production cost.

Application of MIM stainless steel parts:

1. Computer and auxiliary facilities: such as printer parts, magnetic core, striker shaft pin and driving parts;

2. Household appliances: such as watch case, watch chain, electric toothbrush, scissors, fan, golf head, and other parts;

3. Medical device parts: such as dental orthosis frame and forceps;

4. Electrical parts: such as micro motor parts, electronic parts, sensor parts, mobile phones and machine parts;

5. Mechanical parts: small and complex parts of various machines such as cotton loosening machine, textile machine, sewing machine, office machinery and so on;

6. Automobile and ship parts: such as clutch inner ring, rocker arm insert, shift fork sleeve, distributor sleeve, automobile airbag parts and automobile lock.

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 25-30 days after the receipt of the deposit. production will be finished about 20-25days after samples confirma.

process | metal injection molding, powder metallurgy |

applied software | pro-e, CAD, PDF |

material | iron alloy , stainless steel, copper. ceramic, tungsten alloy |

surface finish | black, plating, PVD, polishing, sandblasting |

tolerance precision | ±0.02~0.05mm |

quality system | 100% inspection before shipment |

dimensions | as per customer's requests |

samples qty | 5-10 pcs(for free) |

certification | ISO 9001, TS 16949, IECQQC080000 |

packgae | plastic bag and carton or as customer's requests |

lead time | base on the qty of order(usually 40-45 days) |

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.