Fax:86-0769-82389116

Email:Sales@harber-mim.com

Powder metallurgy mechanical parts refers to the mechanical parts manufactured by powder metallurgy method, also known as sintered mechanical parts. Usually include mechanical structure parts, oil-containing bearings and friction parts; sintered mechanical parts are mainly widely used in agricultural machinery, automobiles, machine tools, instruments, textiles and other machines.

MIM material

| Material | Composition |

| Low alloy steel | Fe-2Ni, Fe-8Ni |

| Stainless steel | 316L, 17-4-PH |

| Tool steel | 42CrMo4, M2, Skd-11, C45 |

| Carbide | WC-Co(6%) |

| Ceramics | Al203, ZrO2, SiO2 |

| Tungsten alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

With over 10 years' experience in powder metallurgy, Harber provides high-end global customers with high-quality components and advanced one-stop solutions. Our zero-defect products covers in such businesses fields as Automotive, Medical application, Houshold, Consumer electronics, Hardware tools and Lock. Best raw materials, strict inspection control and cutting-edge know-how has made Harber a reliable and professional profile to our customers from all over the world. We are sure that Harber can meet any needs from them by using our expertise, credibility and technicality.

Harber Metal has excellent talents in the field of powder metallurgy, mature powder metallurgy production technicians, and long-term cooperation with domestic top powder metallurgy research laboratories. It is a comprehensive high-tech enterprise integrating research, development, production and sales of powder metallurgy structural parts.

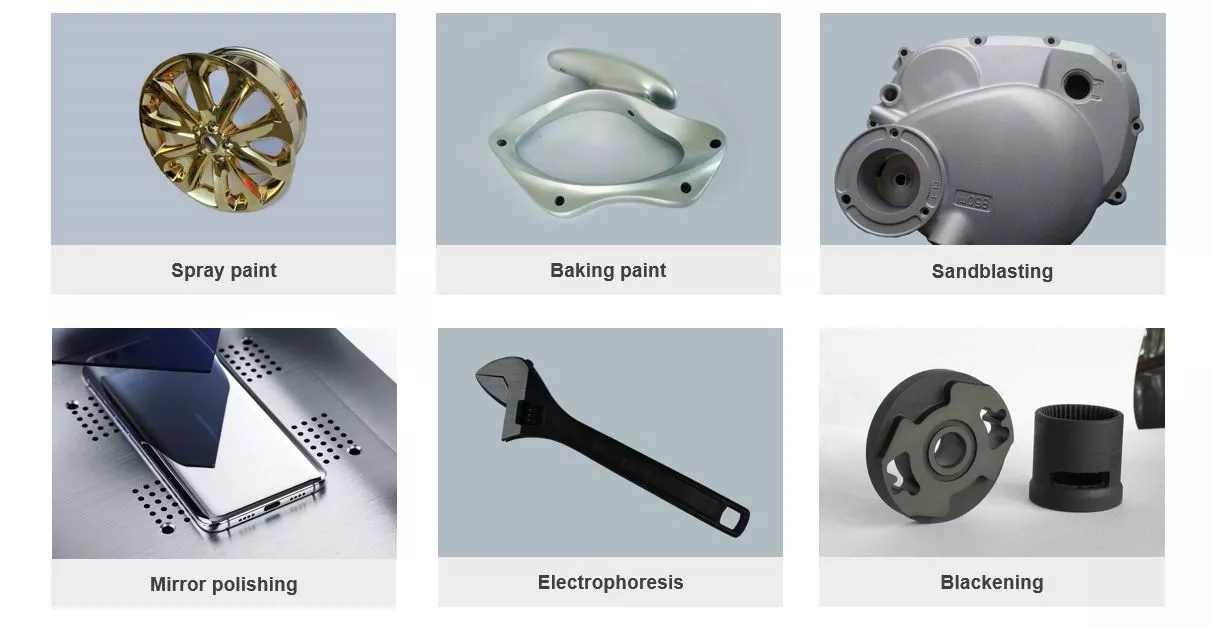

Harber can offer such surface finish (secondary process) as sandblasting, electric polishing, magnetic grinding, laser engraving, PVD, carburizing, Permeability nitrogen and annealing.

process | metal injection molding, powder metallurgy |

applied software | pro-e, CAD, PDF |

material | iron alloy , stainless steel, copper. ceramic, tungsten alloy |

surface finish | black, plating, PVD, polishing, sandblasting |

tolerance precision | ±0.02~0.05mm |

quality system | 100% inspection before shipment |

dimensions | as per customer's requests |

samples qty | 5-10 pcs(for free) |

certification | ISO 9001, TS 16949, IECQQC080000 |

packgae | plastic bag and carton or as customer's requests |

lead time | base on the qty of order(usually 40-45 days) |

Application of MIM Common Products

| Aerospace Industry | Aircraft wing chain, Rocket nozzle, Missile tail, Ceramic turbine blade core |

| Auto industry | Ignition control lock parts, Turbocharger rotor, Valve guide parts, Automotive brake parts, Automotive anti technology backbone parts |

| Electronic industry | Disk drive unit, Cable connector, Electronic housing, Computer print head, Electronic package, Heat sink material |

| Military industry | Mines, Rotors, Plates, Triggers, Armor, Hearts, Constellations, Cluster arrows, Small arrows |

| Medical Industry | Dental orthodontic brackets, Internal suture needles, Living tissue sampling forceps and Child radiation screen cover |

| Daily Necessities | Watchcase, Watchband, Buckle, Golf tee, Shoe buckle, Sports and sports firearms parts, Document binding punch |

| Machinery industry | Special milling cutter, Cutting tool, Micro gear |

Copyright © 2022 Harber Industrial Co.,Ltd precision-mimmetal.com All Rights Reserved. | Sitemap

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.